OKO Protein

Background

Food pioneer Daniel Balderson is bringing an innovative new approach to farming high protein crickets to the UK market.

After graduating from Oxford university, Daniel went to Beijing to teach English. He set up and successfully ran an English school until COVID hit and changes in Chinese government policy meant the school had to close. It was during this time that he came across crickets as a food source. In China they are considered a delicacy.

Back in the UK, Dan’s doctor suggested that he needed to reduce his blood pressure. Dan said “I had hight blood pressure for about a year and was told by the doctor to lose weight – so I changed my diet, started going to the gym and slimmed down a lot. But then I read an article about the environmental impact of the meat industry and its pretty horrific, so I started looking for alternatives. I saw a lot of plant-based options, but they weren’t great or sustainable either.”

“Then I came across inspect protein, particularly crickets. They have the nine essential amino acids we need in the right proportions for growing muscles and recovery after sport, and it is incredibly environmentally friendly. I thought it was a miracle food and went online to get some – but it was so expensive. “

Business Objectives

Through research Dan established that the current cost of UK-produced cricket protein is £70.00 for poor-quality product with a bitter flavour due to the inclusion of cricket waste. Dan’s objective then became to create a high-quality powder at the economically viable price of £12.50 per KG. Going back to first principles, he has developed a low-tech approach that separates the growing and harvesting of the crickets. The model relies on circular outsourcing. OKO breeds the crickets and rears them for 6 days. They are then shipped out to a network of local farmers who maintain the crickets during their growth to maturity, which takes 30 days. They are then collected and brought back to the OKO processing plant for dispatch, washing, drying, and milling.

Working with local farmers provides the opportunity for the farming community to benefit. The set-up fees and space for the growth units are comparatively low, enabling farmers to capitalize on existing spare capacity.

Dan has worked in partnership with the University of Nottingham and the Food and Drink Forum to develop his innovative approach to rearing crickets and producing the powder. They have also had support from a UK government grant to help with food security - Transforming UK Food Systems, Strategic Priorities Fund.

Benefits Compared to Traditional Sources of Animal Protein

The cricket powder is ambient and has a 12-month shelf-life. This greatly reduces the cost of storage and transport compared to traditional meat which is typically stored chilled or frozen. Another benefit is that unlike traditional fresh or frozen meat, it doesn’t shrink during the cooking process.

Global Sustainability

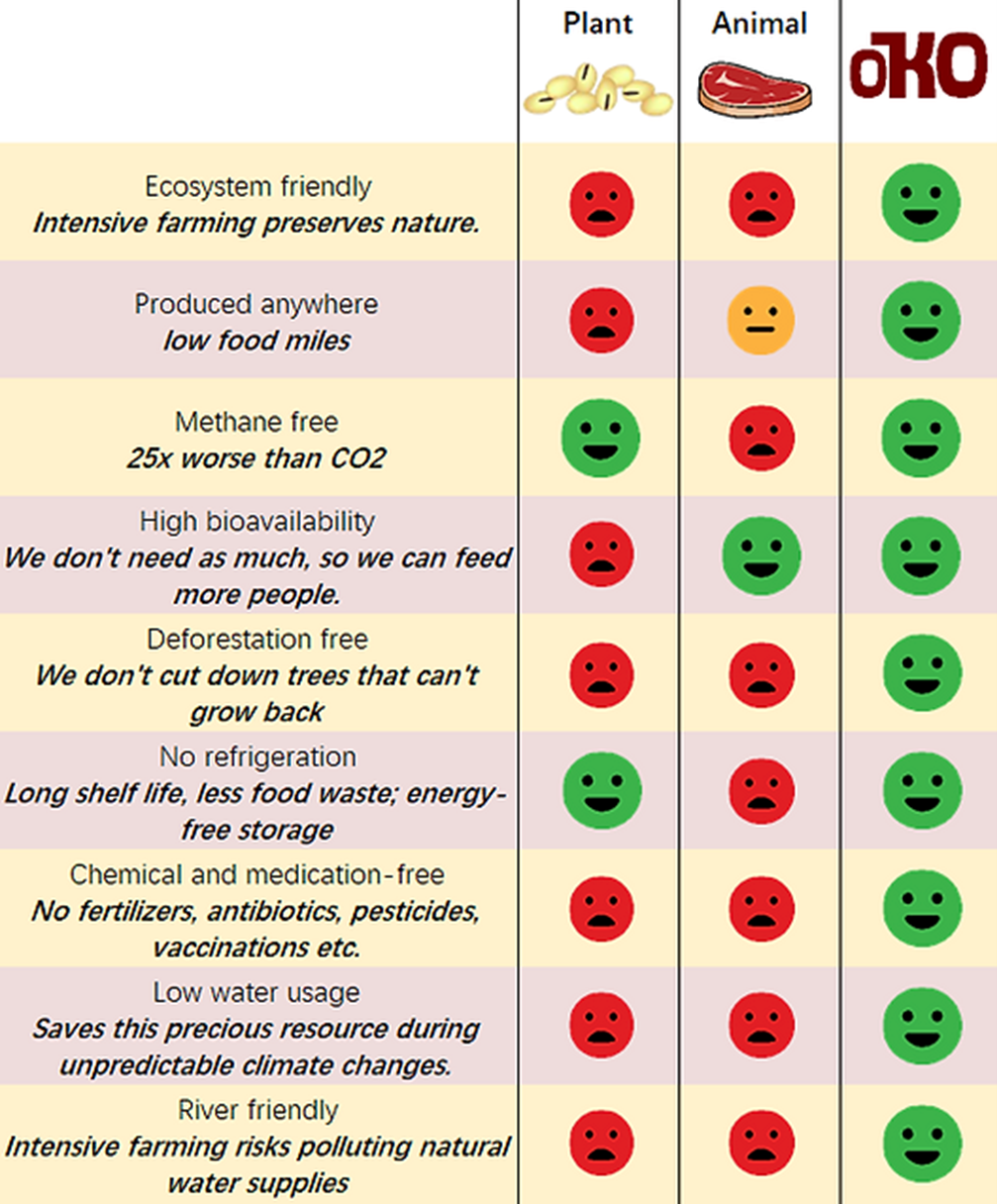

With global demand for protein rising, cricket protein provides an excellent solution because it is much more environmentally sustainable and is more nutritionally complete than many plant-based alternatives. Crickets can be grown almost anywhere. They are omnivores so each region in the world can feed them on whatever is grown locally.

Global Sector Status

There is a great deal of interest and innovation taking place in insect protein across the world with investment finance underpinning the development of high tec production and processing facilities, that are essentially a high tec version of the traditional SE Asian approach to rearing crickets.

For example, Canadian government agency, Agriculture and Agri-Food Canada invested $8.5 million in Aspire, an insect agricultural company, to build a new production facility in Onterio.